Cable Route Planning Software

How does cable route planning software optimize for minimizing signal interference?

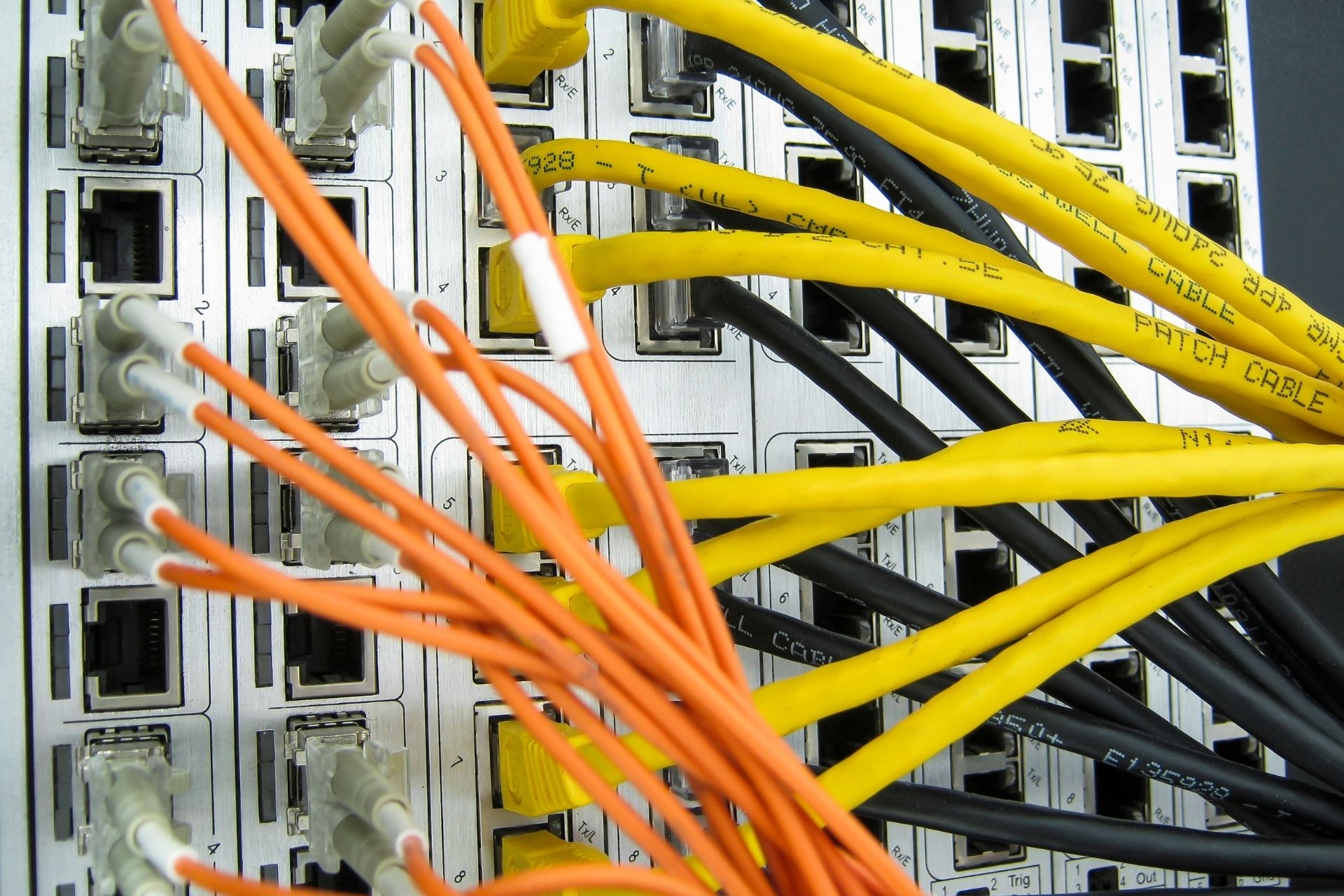

Cable route planning software optimizes for minimizing signal interference by utilizing advanced algorithms that take into account factors such as cable proximity, signal strength, and potential sources of interference. By analyzing these variables, the software can recommend the most efficient route that minimizes the risk of signal degradation or loss due to interference.